Acadia National Park was the prime motivator behind our chosen route. Although it might seem modest on a map, it stands as the crown jewel of the East Coast, boasting a harmonious blend of ocean, mountains, and enchanting historical towns. As the sun heralded a new day, we unfurled our bikes and set our course for Mount Cadillac, the Atlantic seaboard’s highest point and the privileged vantage point for witnessing daybreak in the USA.

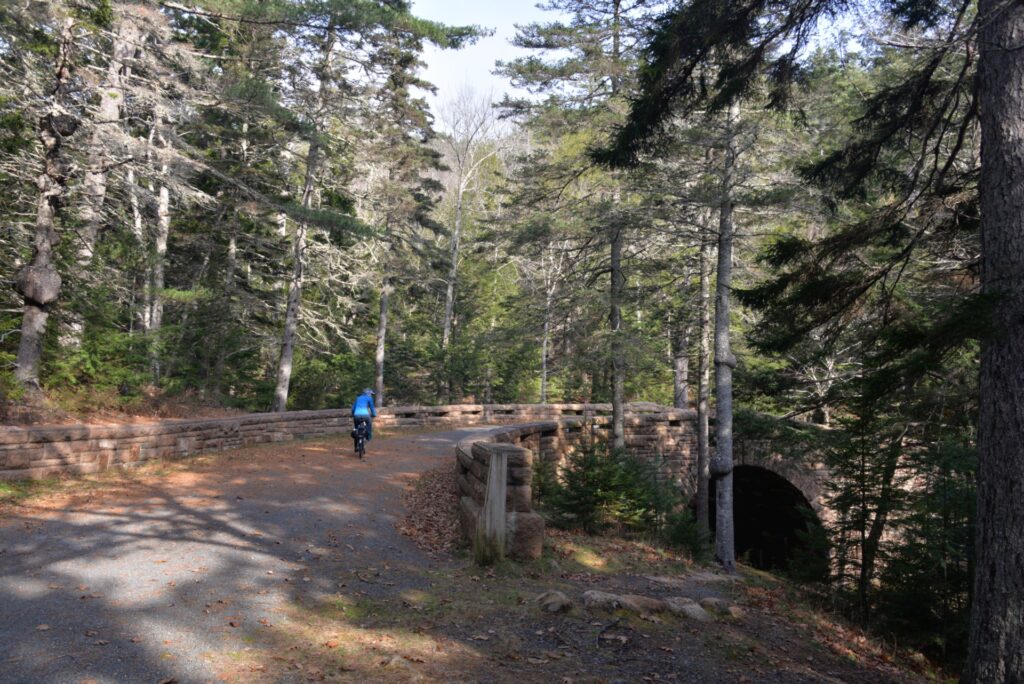

Our biking sojourn along the park’s impeccable trails, known as “carriage roads,” was a pure delight. Constructed between 1913 and 1940 under the patronage of John D. Rockefeller Jr., these roads were initially designed for horse-drawn carriages, offering visitors an immersion in nature free from modern distractions. Winding seamlessly through woods and rocks, these roads are adorned with granite dragon teeth along the edges, and the bridges, crafted from granite, stand as art pieces in themselves.

Upon reaching the end of Bubble Pond, we parted ways with our trusty two-wheelers as the trail inclined steeply. The journey became more adventurous (and rewarding) than we had envisioned, the trail was steep and we even lost our way once, but were able to find the way thanks to Google map. Difficulties didn’t bother us at all, and vice versa we enjoyed every step on the smooth granite rocks cloaked in a thick carpet of moss and lichen evoking our admiration. Towering pines and balsam firs on the cliff’s edges provided visual delights as we ascended, revealing a more breathtaking landscape with each step.

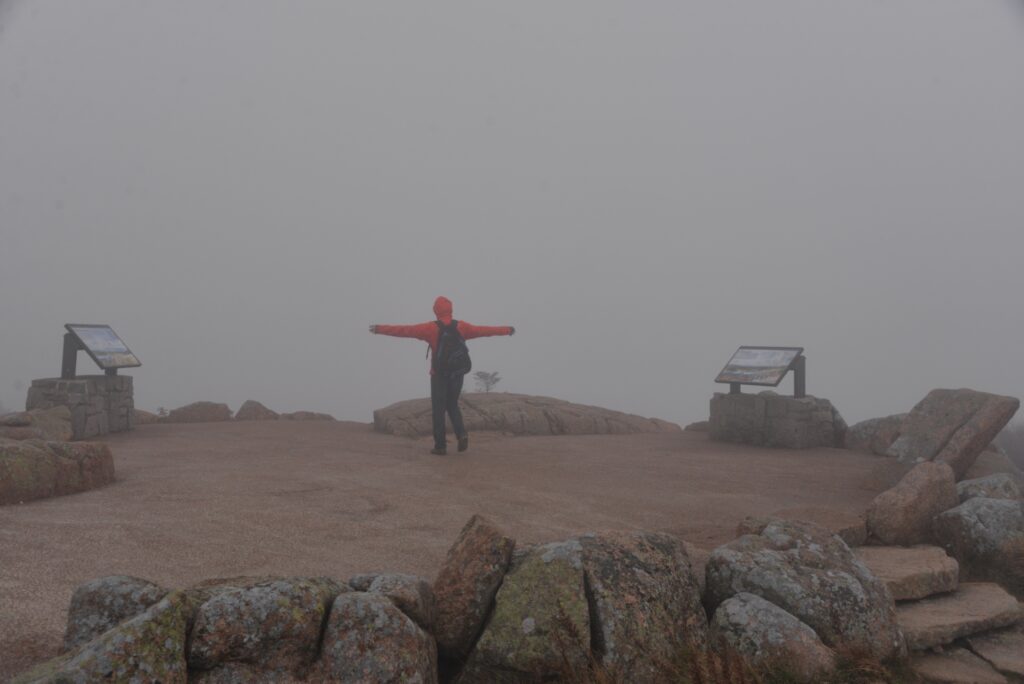

However, as we climbed higher, we noticed some peaks around us veiled by clouds. We began to wonder if we were destined to end up in the clouds too. The allure of mountain hiking lies in the panoramic view from the summit, where, exhausted yet content, you can marvel at the world below. Cadillac promised us an almost 360-degree view!

Alas, upon reaching the end of the trail, we were met with the disappointment of fog and a brisk northern wind, obscuring the promised view. Undeterred, our story took an unexpected turn. As we began our descent with the perspective to continue in the darkness (eventually), a little white van pulled up, and a friendly lady beckoned us to join. Gratefully, we accepted the offer, revelling in the warmth of the cozy van. April, our newfound friend, explained that she had come to Cadillac Mountain to witness the sunset but was thwarted by the weather. Meeting someone with a similar mindset is always a pleasure. Soon, we emerged from the cloud cover, greeted by a breathtaking view below: the ocean adorned with numerous islands. Isn’t it wonderful?

April dropped us off at our bicycles, and we pedalled our way back home (to the boat). The final leg of our journey unfolded in darkness, a regrettable reminder of the short days in November.